A06B-6134-H202#A or A06B6134H202

A06B-6134-H202#A - SERVO/SPINDLE MODULE MDL BiSVPM20/20-11 TYPE A

Repair available at $2300 including UPS GND shipping. 2 day turnaround, 12-month warranty.

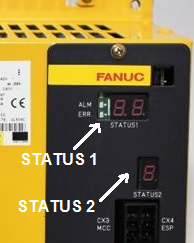

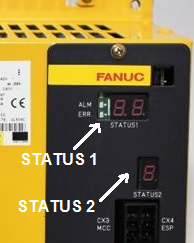

A06B-6134-H202#A Series has two LED status indicators.

Alarm Code Description

Status 1

01 Motor overheat

(Alarm 9001, 7101)

02 Excessive speed deviation

(Alarm 9002, 7102)

03

DC link fuse is blown

(Alarm 9003, 7103)

04 Open

phase in the converter

main

power supply (Alarm

607, 9004, 7104)

6, 06 Temperature sensor disconnected

(Alarm 9006, 7106)

7, 07 Excessive speed

(Alarm 9007, 7107)

9, 09 Main circuit overload/IPM overheat

(Alarm 9009, 7109)

11 Converter: DC link overvoltage

(Alarm 439, 9011, 7111)

12 IPM alarm

(Alarm 9012, 7112)

18 Program sum check error

(Alarm 750)

19 Excessive offset of the phase

U current detection circuit

(Alarm 750)

20 Excessive offset of the phase

V current detection circuit

(Alarm 750)

21 Position sensor polarity setting

is incorrect

(Alarm 9021, 7121)

24 Serial transfer data error

(Alarm 749)

27 Position coder disconnected

(Alarm 9027, 7127)

29 Short-period overload

(Alarm 9029, 7129)

30 Overcurrent in the converter input

circuit

(Alarm 437, 9030, 7130)

31 Motor lock alarm

(Alarm 9031, 7131)

32 Serial communication LSI RAM

error

(Alarm 9032, 7132)

33 Converter: DC link precharge

failure

(Alarm 442, 9033, 7133)

34 Parameter data out of the

allowable

range

(Alarm 9034, 7134)

35 Gear ratio parameter error

(Alarm 9035, 7135)

36 Error counter overflow

(Alarm 9036, 7136)

37 Speed detector parameter error

(Alarm 9037, 7137)

41 Position coder one-rotation signal

detection error

(Alarm 9041, 7141)

42 Position coder one-rotation signal

not detected

(Alarm 9042, 7142)

46 Position sensor one-rotation signal

detection error during thread cutting

(Alarm 9046, 7146)

47 Position coder signal error

(Alarm 9047, 7147)

50 Excessive speed command calculation value

during spindle synchronization

(Alarm 9050, 7150)

51 Converter: DC link undervoltage

(Alarm 433, 9051, 7151)

52 ITP signal error I

(Alarm 9052, 7152)

53 ITP signal error II

(Alarm 9053, 7153)

54 Current overload alarm

(Alarm 9054, 7154)

58 Converter: main circuit overload

(Alarm 431, 9058, 7158)

73 Motor sensor disconnected

(Alarm 9073, 7173)

75 CRC test alarm

(Alarm 9075, 7175)

79 Abnormal initial test operation

(Alarm 9079, 7179)

81 Motor sensor one-rotation signal

detection error

(Alarm 9081, 7181)

82 Motor sensor one-rotation signal

not detected

(Alarm 9082, 7182)

83 Motor sensor signal error

(Alarm 9083, 7183)

84 Spindle sensor disconnected

(Alarm 9084, 7184)

85 Spindle sensor one-rotation signal

detection error

(Alarm 9085, 7185)

86 Spindle sensor one-rotation signal

not detected

(Alarm 9086, 7186)

87 Spindle sensor signal error

(Alarm 9087, 7187)

A

Program ROM error (Alarm

749)

A1

Program ROM error (Alarm

749)

A2

Program ROM error

(Alarm 749)

b0 Communication error between

amplifier and module

(Alarm 9010, 7198)

(CXA2C)

b1 Converter: control power supply

low voltage

(Alarm 432, 9111, 7198)

C0

Communication data alarm

(Alarm 9120)

C1

Communication data alarm

(Alarm 9120)

C2

Communication data alarm

(Alarm 9120)

STATUS 2

Alarm Description

2

Inverter: control power supply

undervoltage

(Alarm 434)

5

Inverter: DC link undervoltage

(Alarm 435)

b Inverter: motor current alarm (L axis)

(Alarm 438)

C

Inverter: motor current alarm (M axis)

(Alarm 438)

d Inverter: motor current alarm (N axis)

(Alarm 438)

8. Inverter: IPM alarm (L axis)

(Alarm 449)

9. Inverter: IPM alarm (M axis)

(Alarm 449)

A. Inverter: IPM alarm (N axis)

(Alarm 449)

F

Inverter: radiator cooling fan stopped

(Alarm 601)

6 Inverter: overheat

(Alarm 602)

8.

Inverter: IPM alarm (OH) (L axis)

(Alarm 603)

9. Inverter: IPM alarm

(OH) (M axis) (Alarm 603)

A. Inverter: IPM alarm

(OH) (N axis) (Alarm 603)

P Amplifier and module

communication error (Alarm 604)

U

FSSB communication error (COP10B)

A06B6134-H202#A B65325E Manual

βiSVSP A06B-6134-H202#A Advantages

● All-in-one packaged Servo Amplifier: (servo 3 axes + spindle 1 axis): Fewer cable wiring are achieved by all-in-one structure.

● Energy Saving: Power source regeneration returns the deceleration energy of the motor to the power source.

● Addition of 2nd FSSB connector: Easy connection of multiple βiSVSPs or additional amplifier.

● Gravity-axis drop prevention function at power failure: Tool and work of machine is protected from breakage at power failure by activating the

motor brake quickly using built-in power failure detection function.

● Cs contouring control: For spindle separated sensor, αi BZ sensor is

supported to Cs Contouring control in addition to αi Position coder.

βi SVPM2-11i TypeA

A06B-6134 -H202#A

A16B-2101-0021

A20B-2101-0012

A20B-2902-0670

Other βiSVSP Units:

A06B-6134-H201#A,

A06B-6134-H202#A,

A06B-6134-H203#A

A06B-6134-H201#C, A06B-6134-H202#C,

A06B-6134-H203#C

A06B-6134-H301#A, A06B-6134-H302#A,

A06B-6134-H303#A

A06B-6134-H301#C, A06B-6134-H302#C, A06B-6134-H303#C