KFAS: Fanuc CNC Parts, Service, & Repair

Fanuc 16/ Fanuc 18 CNC Status Display and Details of Diagnostics

The status of the CNC can be monitored at all times.

If the control does not issue an alarm, press the DGNOS button to display the contents of the following diagnostics:

Display of status when a command is not apparently executed (DGN No. 000 – 015)

000: WATING FOR FIN SIGNAL

Meaning: M, S, T function is being executed

001: MOTION

Move command in automatic operation is being executed

002: DWELL

Dwell is being executed

003: IN–POSITION CHECK

In-position check is being performed

004: FEEDRATE OVERRIDE 0%

Override is set to 0%

005: INTERLOCK/ START–LOCK

Interlock is on.

006: SPINDLE SPEED ARRIVAL CHECK

Waiting for spindle speed arrival signal to turn on

010: PUNCHING

Data is being output via reader puncher interface

011: READING

Data is being input via reader puncher interface

012: WAITING FOR (UN) CLAMP

Waiting for index table clamp/unclamp indexing start or

after B axis is indexed

013: JOG FEEDRATE OVERRIDE 0%

Jog override switch is set at 0%

014: WAITING FOR RESET, ESP, RRW OFF

The emergency stop, external reset, reset & rewind or reset key is on.

015: EXTERNAL PROGRAM NUMBER SEARCH

External program number search is active.

016: BACKGROUND ACTIVE

Background Edit is being used.

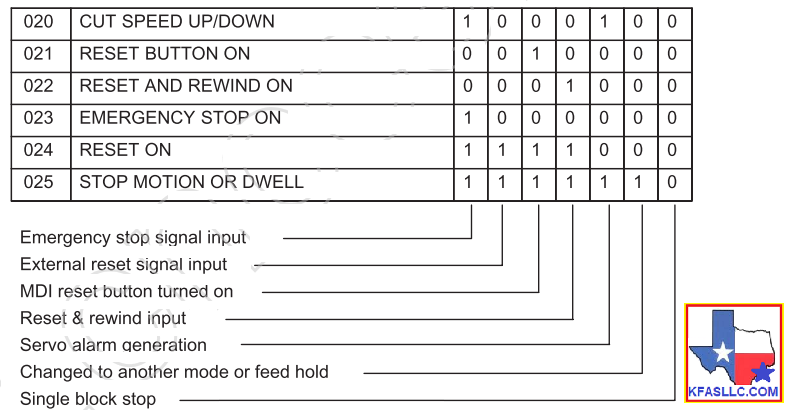

020: CUT SPEED UP/ DOWN

Set when emergency stop turns on or when servo alarm occurs

021: RESET BUTTON ON

Set when reset key turns on

022: RESET AND REWIND ON

Reset and rewind turned on

023: EMERGENCY STOP ON

Set when emergency stop is turned on

024: RESET ON

Set when external reset, emergency stop, reset

or reset & rewind key is on.

025: STOP MOTION OR DWELL

This status is set to 1 in the following cases.

(1) External reset is set to on.

(2) Reset & rewind is set to on.

(3) Emergency stop is set to on.

(4) Feed hold is set to on.

(5) The MDI panel reset key turned on.

(6) Switched to the manual mode (JOG/HANDLE/INC).

(7) Other alarm occurred.

Causes for CYCLE START LED is turned OFF

020 CUT SPEED UP/DOWN

021 RESET BUTTON ON

022 RESET AND REWIND ON

023 EMERGENCY STOP ON

024 RESET ON

025 STOP MOTION OR DWELL

(See below)

TH alarm statuses (No. 030, 031)

030: CHARACTER NUMBER TH DATA

The position of the character which turned TH alarm on is displayed

031: TH DATA

Read code of character which turned TH alarm on

The details of servo alarm 4x4 are provided by the following DGN,

No. 200 #7 #6

#5

#4 #3

#2 #1

#0

OVL LV OVC

HCAL HVAL DCAL FBAL OFAL

OVL: An overload alarm occurred.

The thermal overload has operated. Either an overheat has occurred, the thermal device has defected,

or the cable is broken.

LV: A low voltage alarm has occurred. Either the input voltage is low or the MCC is defective.

OVC: An overcurrent alarm has occurred. Please check cutting conditions, motor

current waveform or digital servo parameter.

HCAL: An abnormal current alarm has occurred. Please check the transistor module of

the amplifier or the servo motor for short.

HVAL: An overvoltage alarm has occurred. Please check the input voltage,

regenerative circuit or servo motor.

DCAL: A regenerative discharge alarm has occurred. Please check the connection of

the discharge unit, condition of discharge transistor or amount of acc/dec.

FBAL: A disconnect of the pulse coder has occurred. A defective pulse coder or wire

break may cause the alarm. Also, please check the parameter for setting of feedback type or shield of the cable.

OFAL: An overflow alarm has occurred. Incorrect parameter of the digital servo is most

possible cause.

No. 202 #7

#6 #5

#4 #3

#2 #1

#0

ALD

EXPC

ALDF EXPC

Details

OVL Alarm 1

0 Overheat detected at the Motor

0 0

Overheat detected at the amplifier

FBAL Alarm 1

0 Disconnect detected by hardware

0 0

Disconnect detected by software

1 1

Separate pulse coder detected by software.

The details of a serial pulse coder Alarm 319, 329, 339, 349 are indicated by the following diagnostics:

No. 203 #7

#6 #5

#4 #3

#2 #1

#0

SFLG CSAL BLAL PHAL SCAL

BZAL CKAL SPHAL

SFLG: This is not an alarm bit. It is set = 1 when serial pulsecoder is used.

CSAL: A check sum alarm occurred. The serial pulsecoder is defective.

BLAL: A low battery voltage alarm has occurred. Please replace the battery.

PHAL: An abnormal phase data alarm has occurred. Either the pulsecoder is defective

or the cable is faulty.

SCAL: An abnormal rotation speed count alarm has occurred. The pulsecoder is

defective.

BZAL: A battery zero alarm has occurred. The pulsecoder is powered for the first time.

Please check that the battery is properly connected and perform a zero return.

CKAL: A clock alarm occurred. Replace the pulsecoder.

SPHAL: An abnormal software phase detect alarm has occurred. Either the pulsecoder

or cable is faulty.

No. 300 SVERR

The amount of position following error is displayed.

No. 301 ABSMT

The machine position is displayed.

© Copyright KFASLLC Houston, Texas, USA

© Copyright KFASLLC Houston, Texas, USA