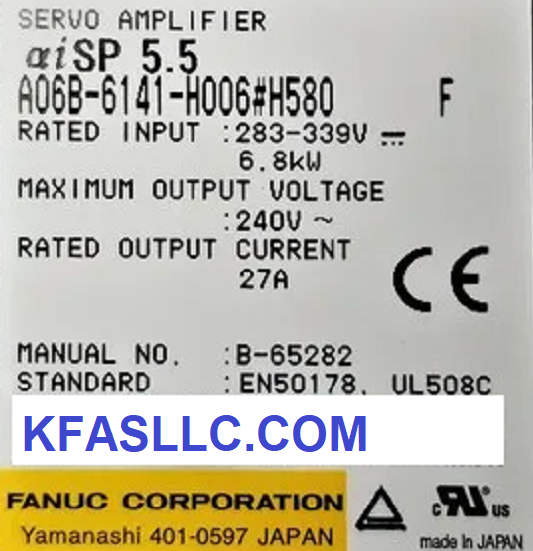

A06B-6141-H006#H580 AiSP-5.5

$3,000 ($650

Exchange Credit Available) ![]()

Rated INPUT: 283-325VDC 6.8kW

Rated OUTPUT: 230VAC 27A

Related technical information Connection Diagram

A06B-6141-H006 Alpha-i Spindle Amplifier Module uses internal cooling fan A90L-0001-0510

Related Part NumbersKFASLLC kfasllc.com

A16B-2203-0651A06B-6141-H006 is part of Fanuc Alpha-i Series family with advanced features including

・High mechanical precision and low vibration making it possible to directly connect to the spindle achieving high mechanical precision and low

vibration (V3).

・Utilizes Power source regeneration technology to return regeneration energy of the motor to a power source. Compared with the resistor regeneration, power consumption is greatly reduced.

・Compact, reduced Wiring utilizing fiber optics communications and easy maintenance features such as ability to replace cooling fans without disassembling the unit.

・Center-through-coolant is available by direct connection with the spindle of a machining center. Air cooled αiIT series and oil cooled αiIL series are available.

© Copyright KFASLLC Houston, Texas, USA

© Copyright KFASLLC Houston, Texas, USA